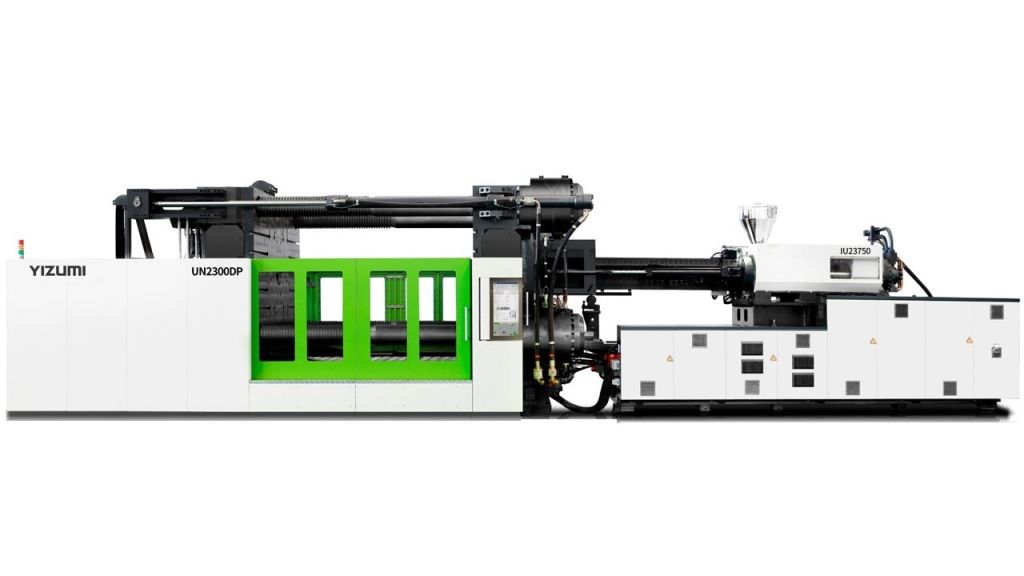

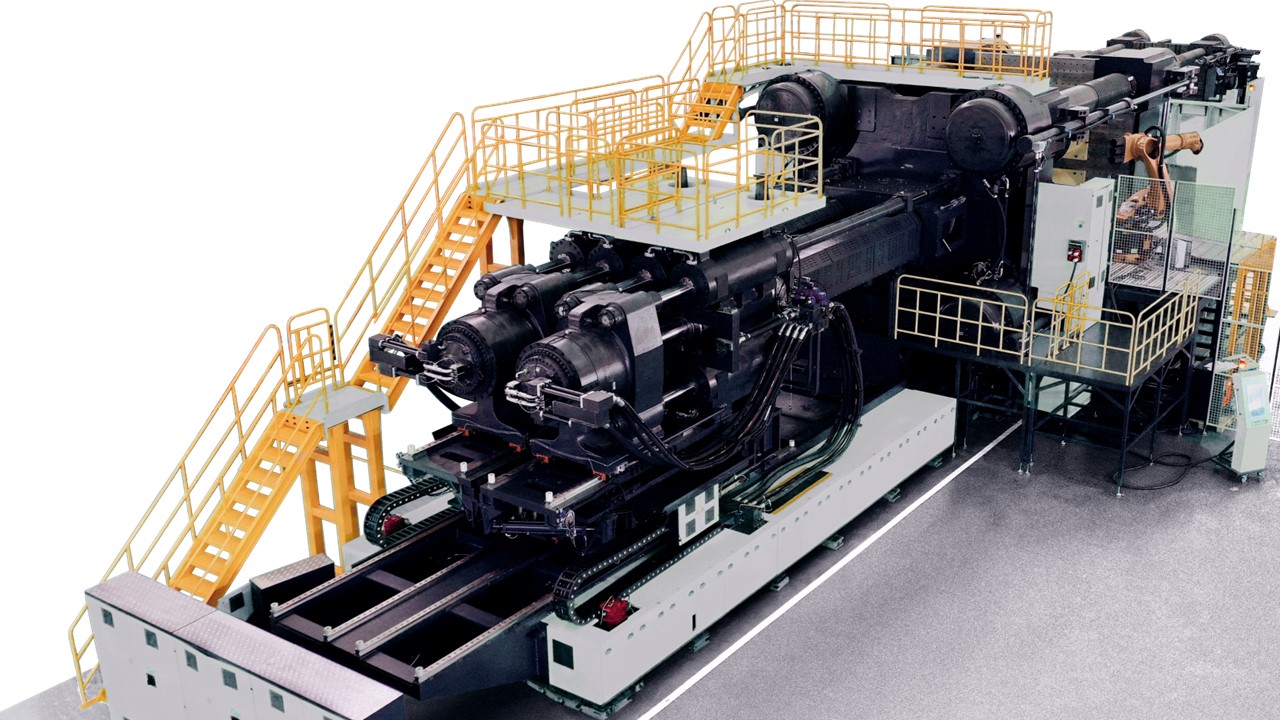

DP series from 5000 kN to 90000 kN

The high-tech two-platen molding machine offering you a unique performance, for the production of large parts.

DP

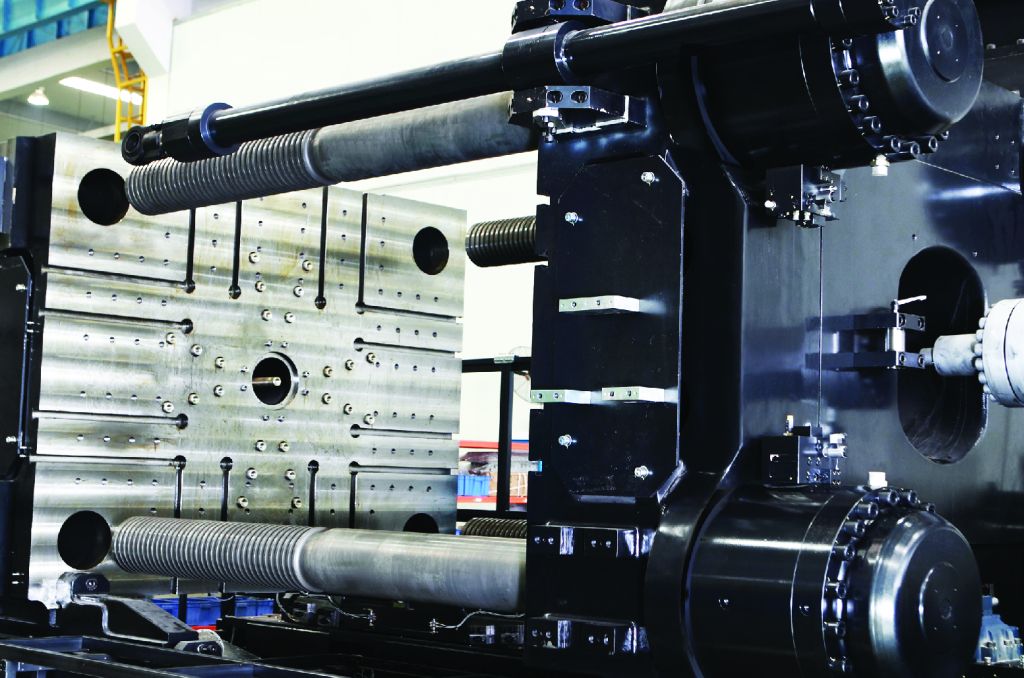

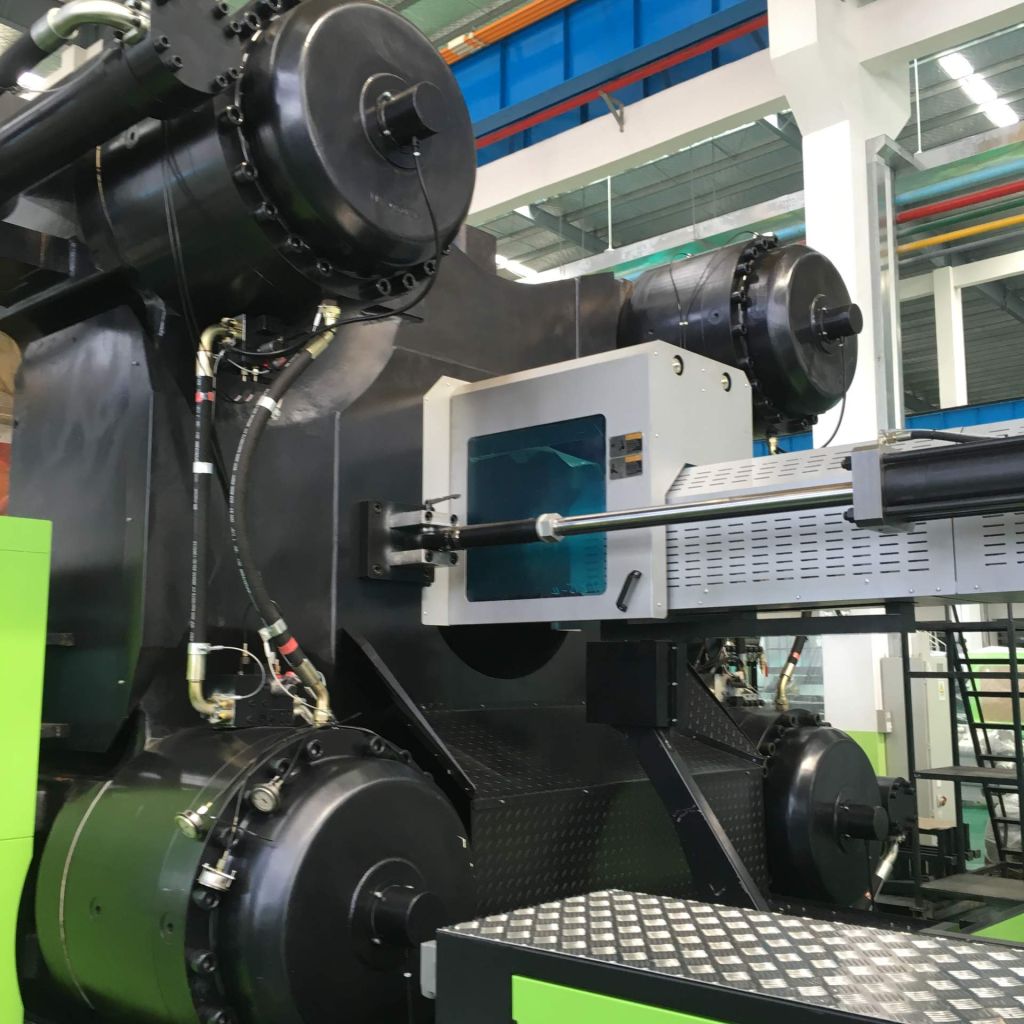

Clamping unit

- 30% saving in floor space.

- High rigidity platen design adapted to large molds, allowing excellent clamping distribution.

- Tie bar free and rapid approach cylinders offer shorter closing and opening cycle times, smooth movement, greater energy savings and reduced maintenance.

- High-pressure, short-stroke clamping cylinders optimize pressure build-up time and promote sensitive mold safety.

- Contactless, magnetostrictive displacement sensors to measure the position of each tie bar.

- The excellent guidance of the plates guarantees increased parallelism precision, reducing mold maintenance costs and improving the quality of the molded part.

- Ejector design for user-friendly access.

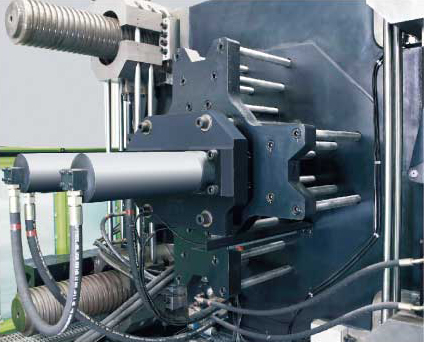

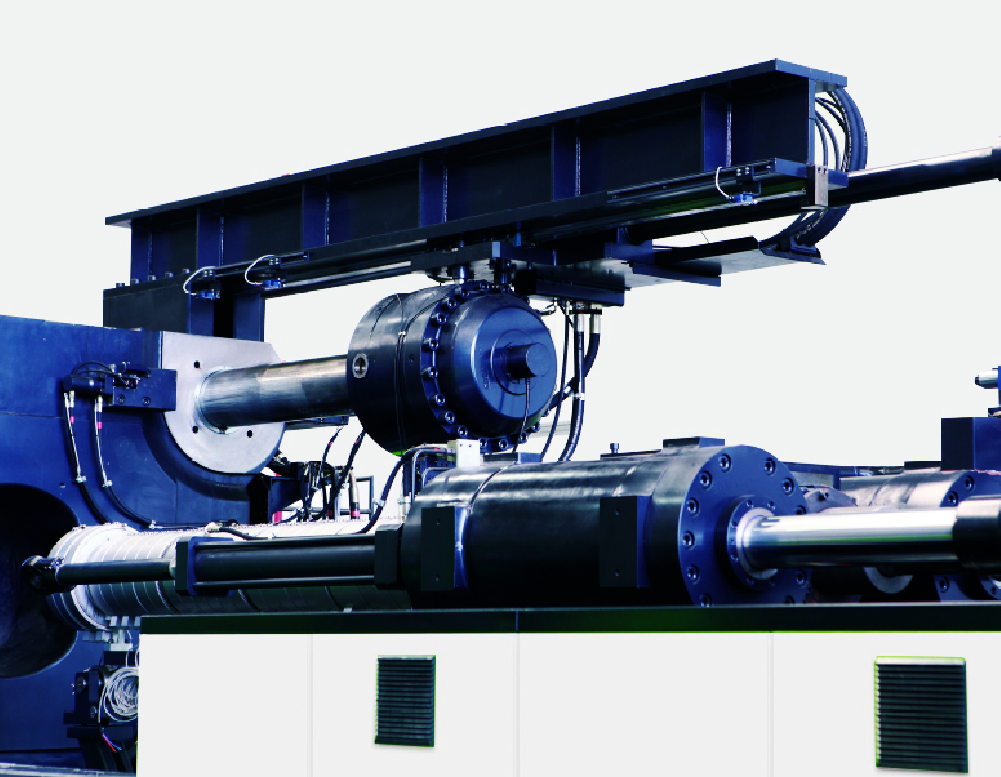

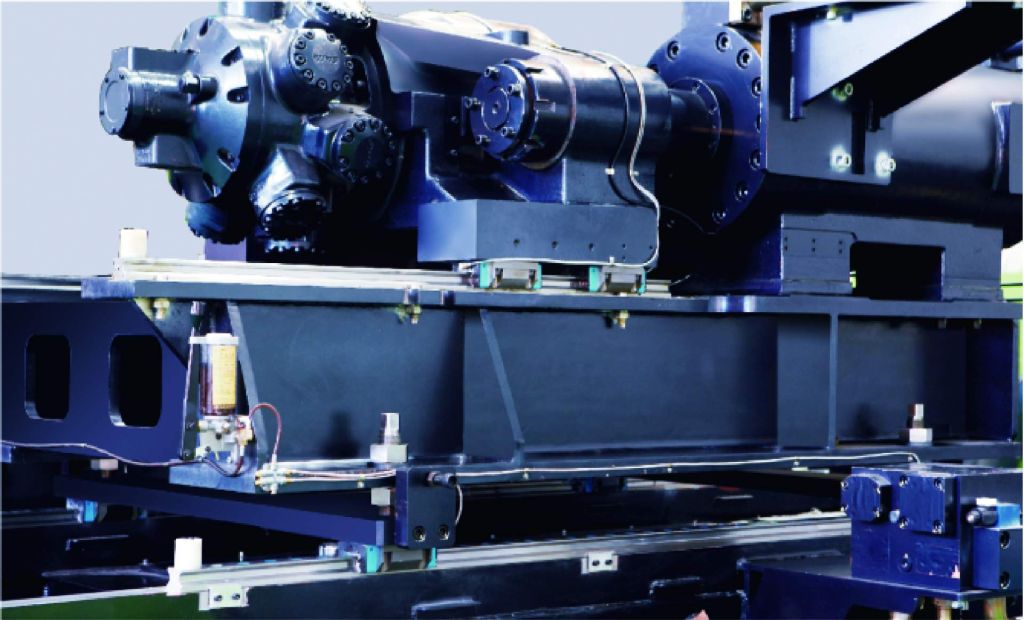

Injection unit

- The modular injection unit can be combined with different clamping units and different screw and cylinder assemblies offering a wide variety of injection solutions according to your needs.

-

The closed loop by servo-valve on the injection as standard across the entire range allows great precision and repeatability.

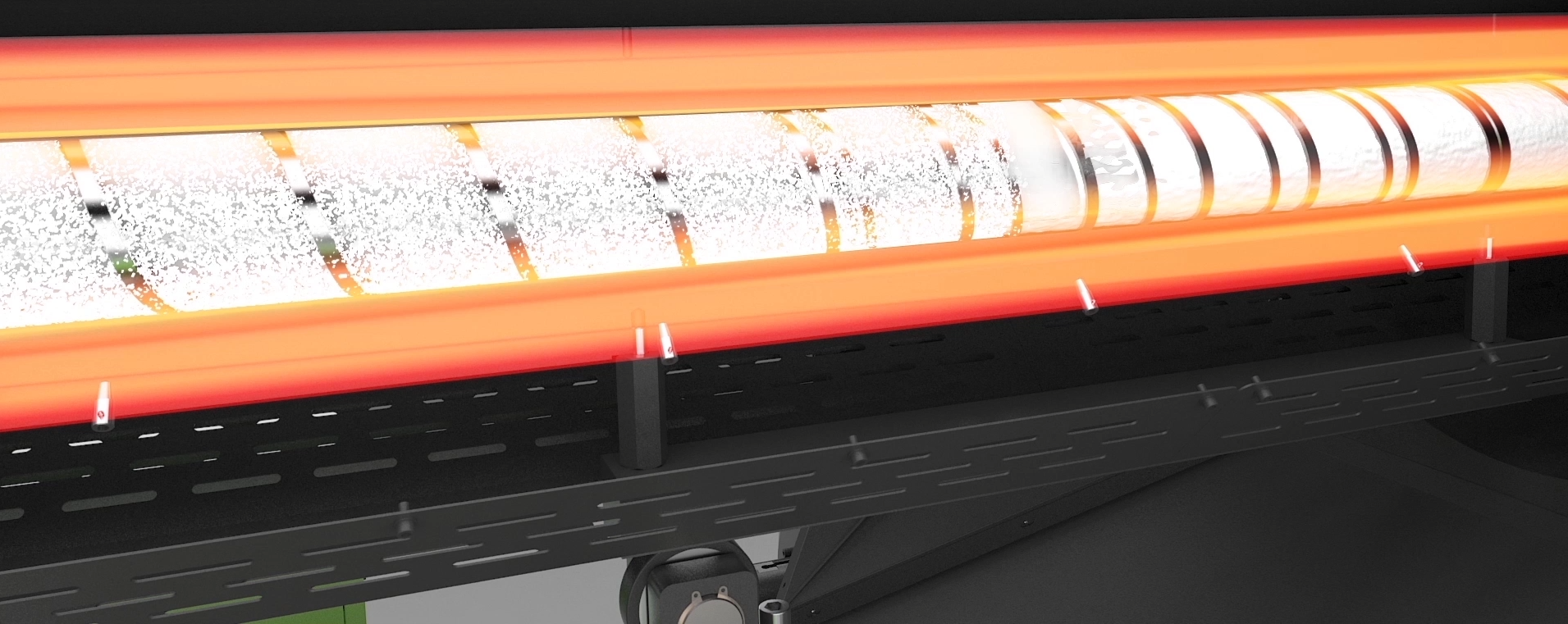

- Ceramic heater bands and barrel insulation protection for better temperature stability and efficiency reducing energy consumption.

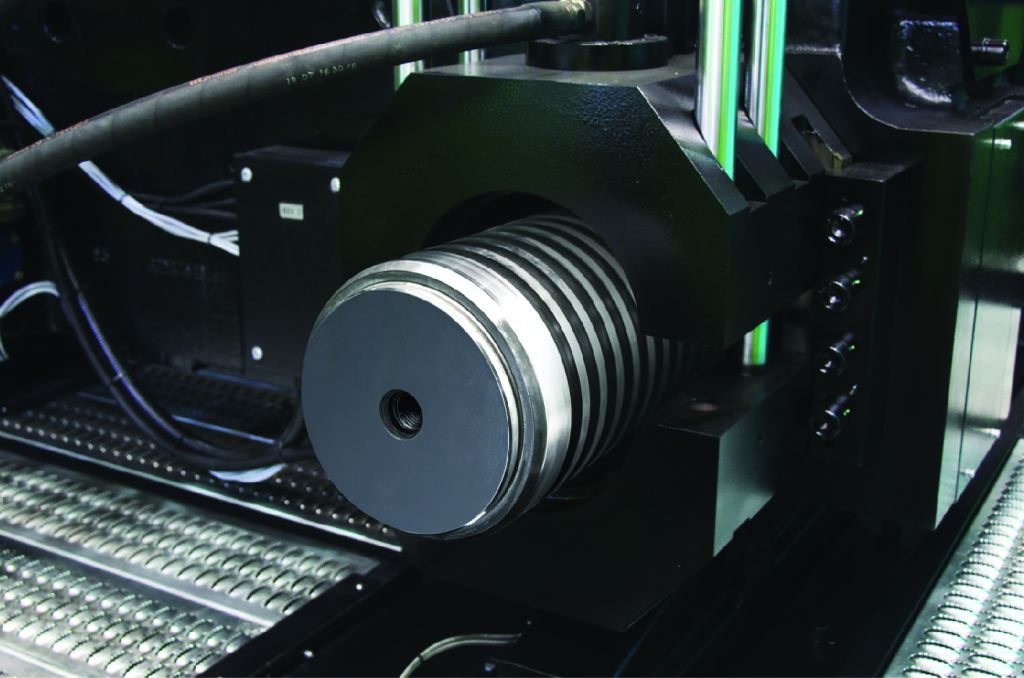

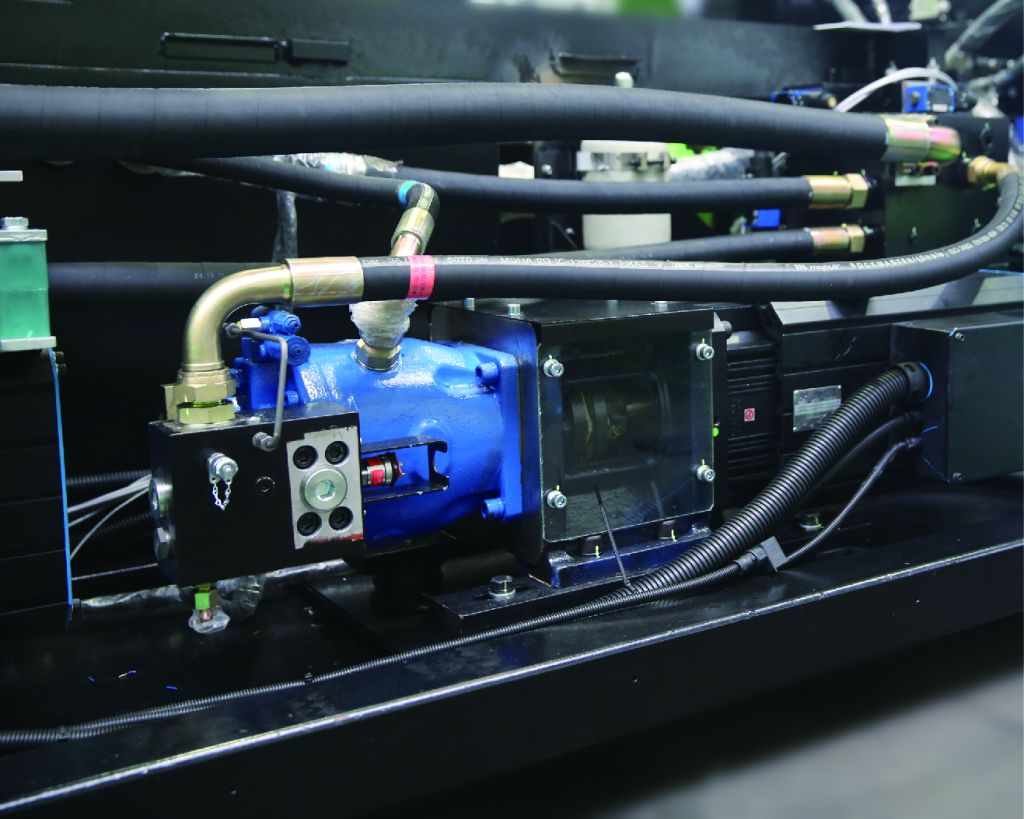

- Screw driven by high torque hydraulic motor (electric motor available as an option)

-

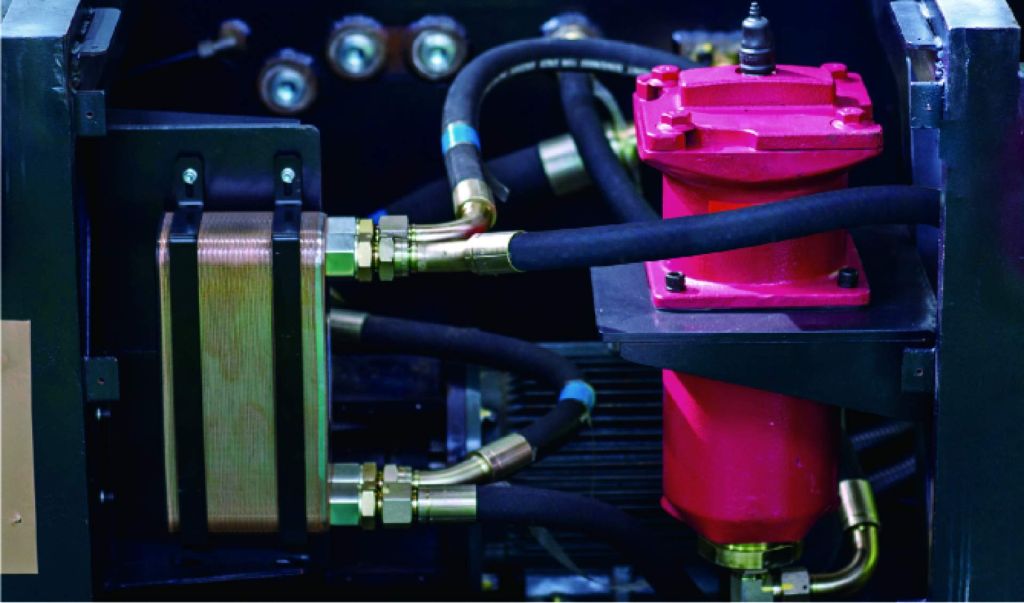

The entire range of machines is equipped with a patented servo-motor-pump system which provides the necessary pressure and flow at a high response rate for energy savings comparable to all-electric injection presses.

Control system

- Intuitive interface on 21″ 100% touch screen

- “SPC”, “QDP” functionality, graphics pages, energy saving optimization page.

- Possibility of cycle management by “sequencer” function, programming of free cores.

Options

- Various options can be added to the range such as: integrated mold heating zones, shutt off check valve control, hydraulic or pneumatic shutt off nozzle, retractable tie bars, magnetic platens, etc…

Do you need information?

Do not hesitate to contact us.