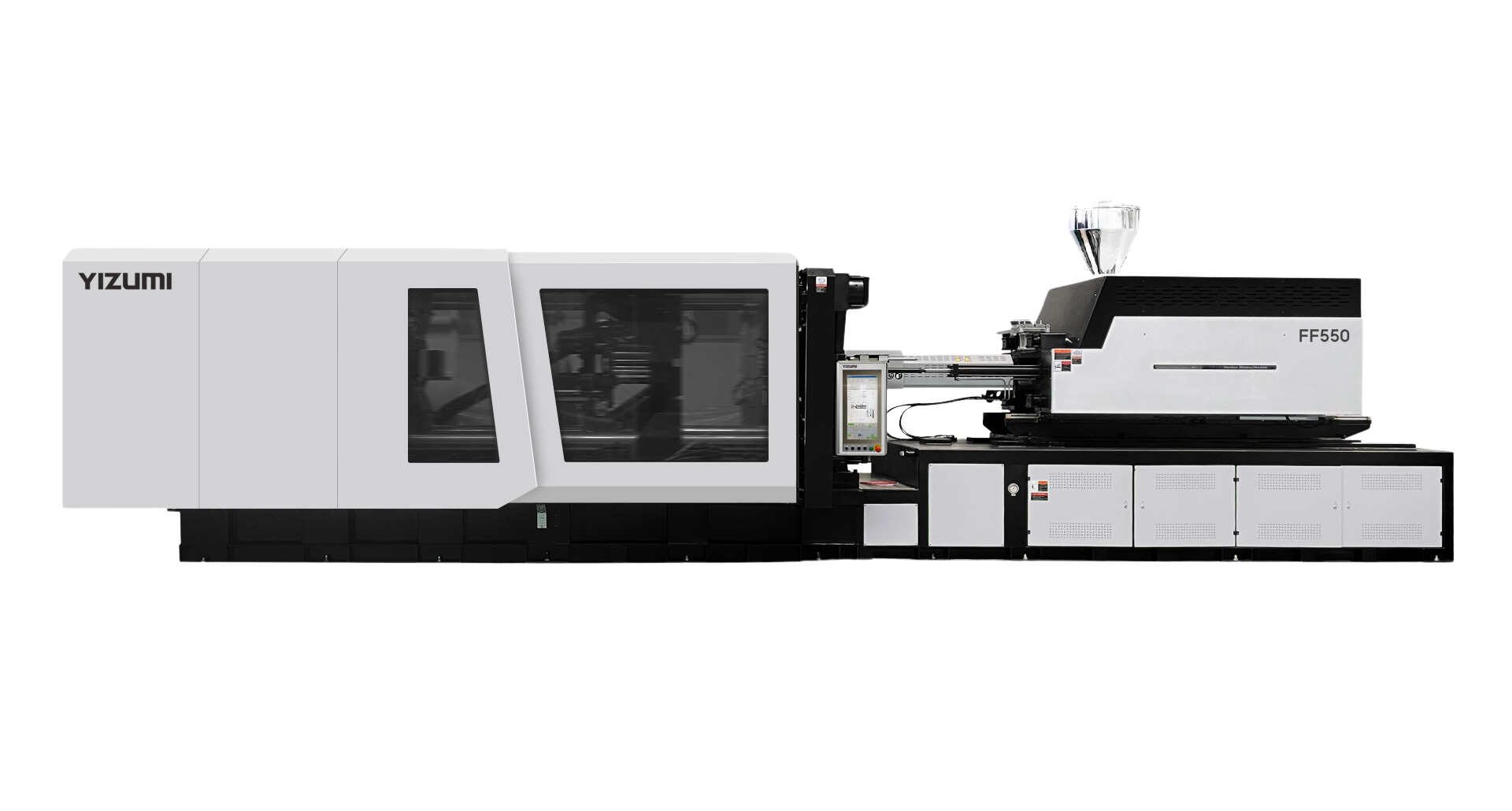

FF Series

Innovative plastic injection using electrical technology, the answer to today’s market needs.

Available from 150 kN to 13800 kN

FF

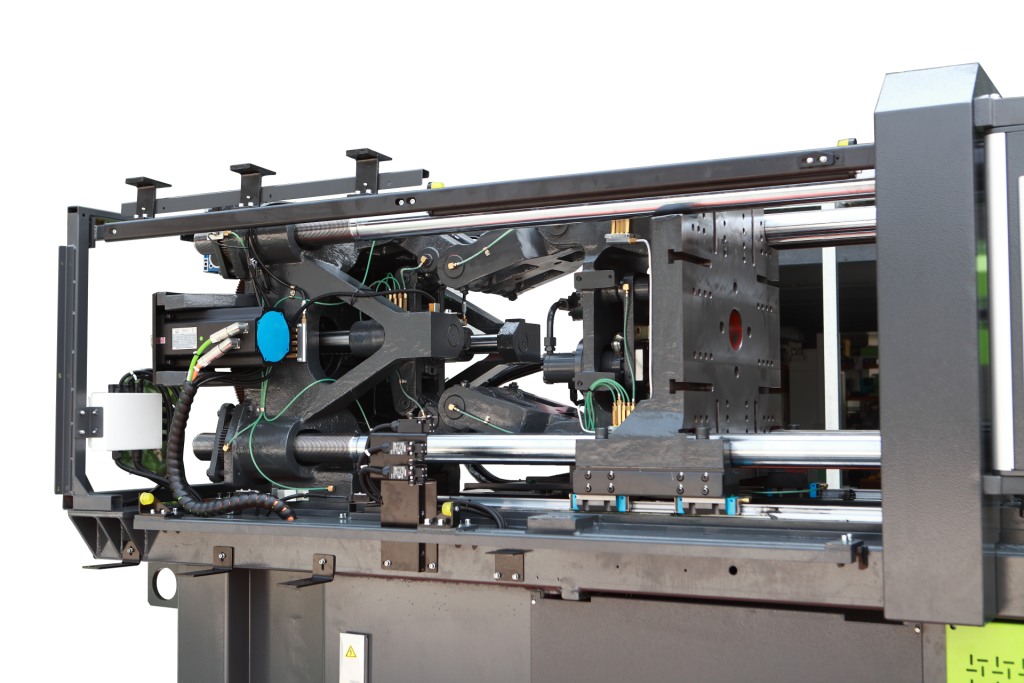

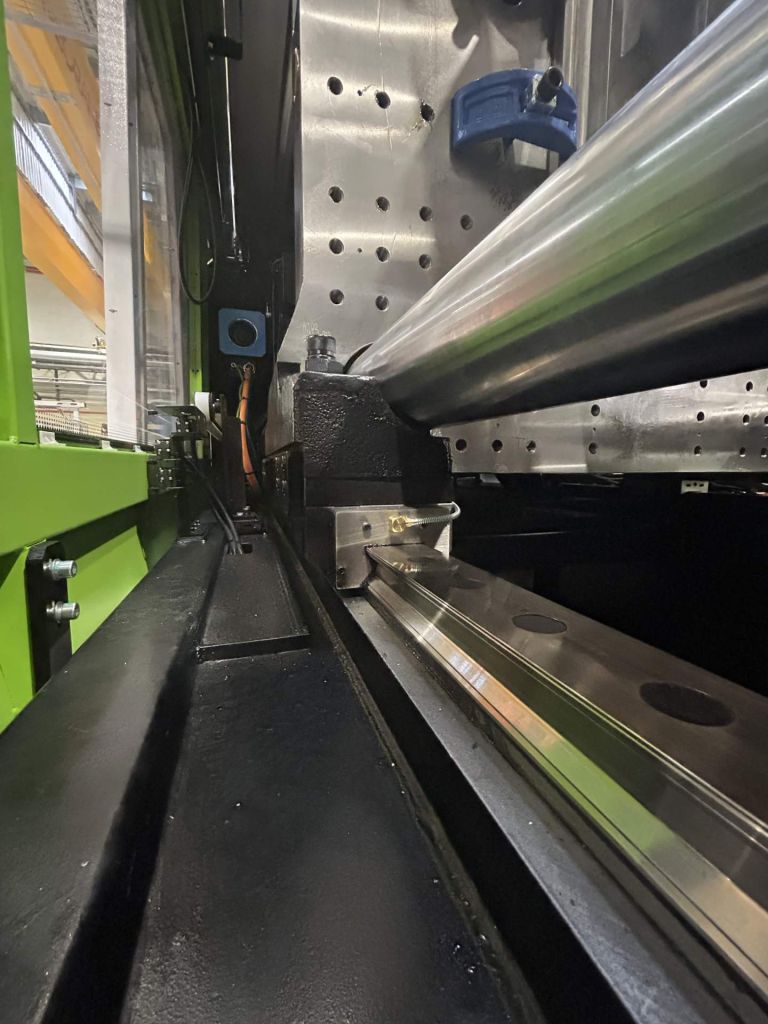

- The clamping unit uses Tie-Bar Free (TBF) technology, reducing any friction and improving the fluidity and the stabiliy of the movements and providing significant energy savings.

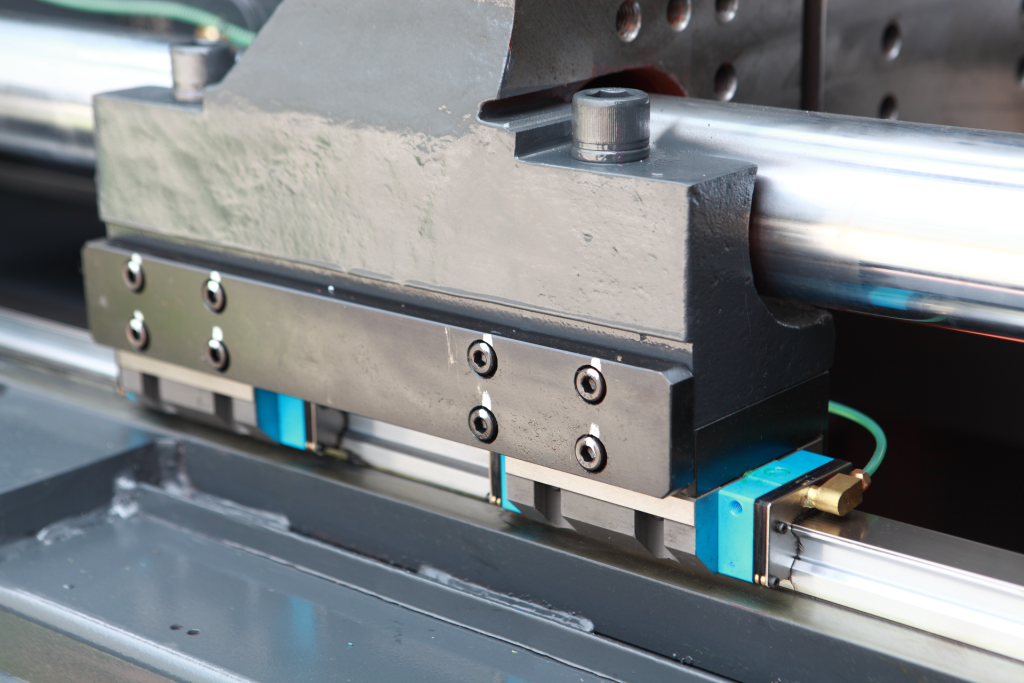

- Prismatic rail guidance (TLGS), for faster mold opening and closing movements, increasing the weight capacity of the molds.

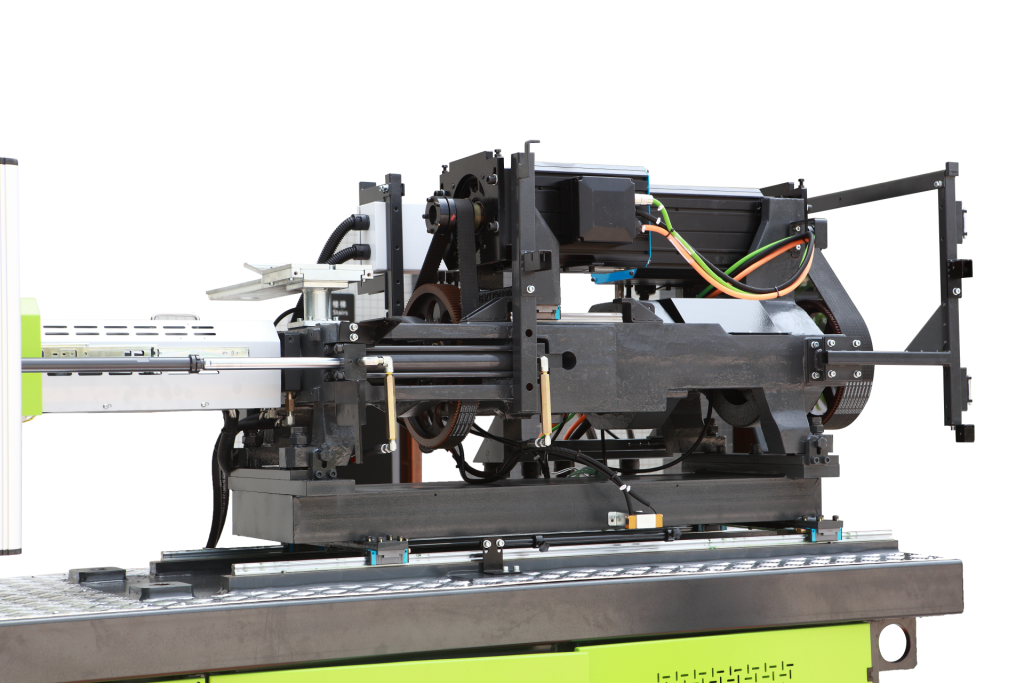

- Double linear-guide injection unit design for optimum precision and speed of movement, and stability of carriage force over time.

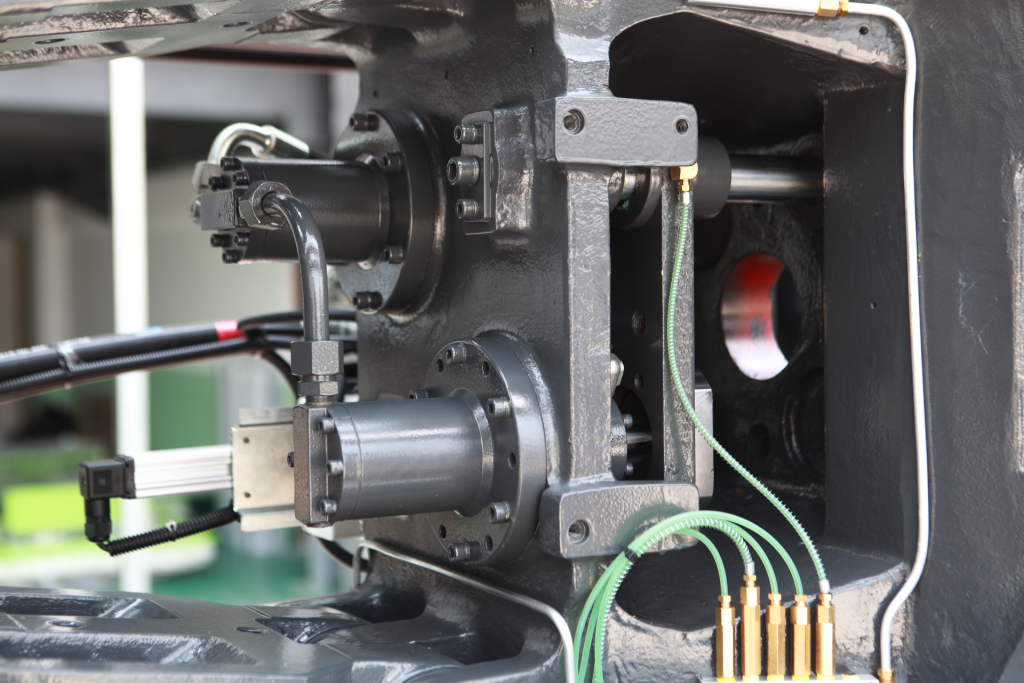

- SCD (Servo Direct Control) system, faster response time for plasticizing, injection, mold opening and closing movements.

- Fully automated lubrication system for clamping and injection.

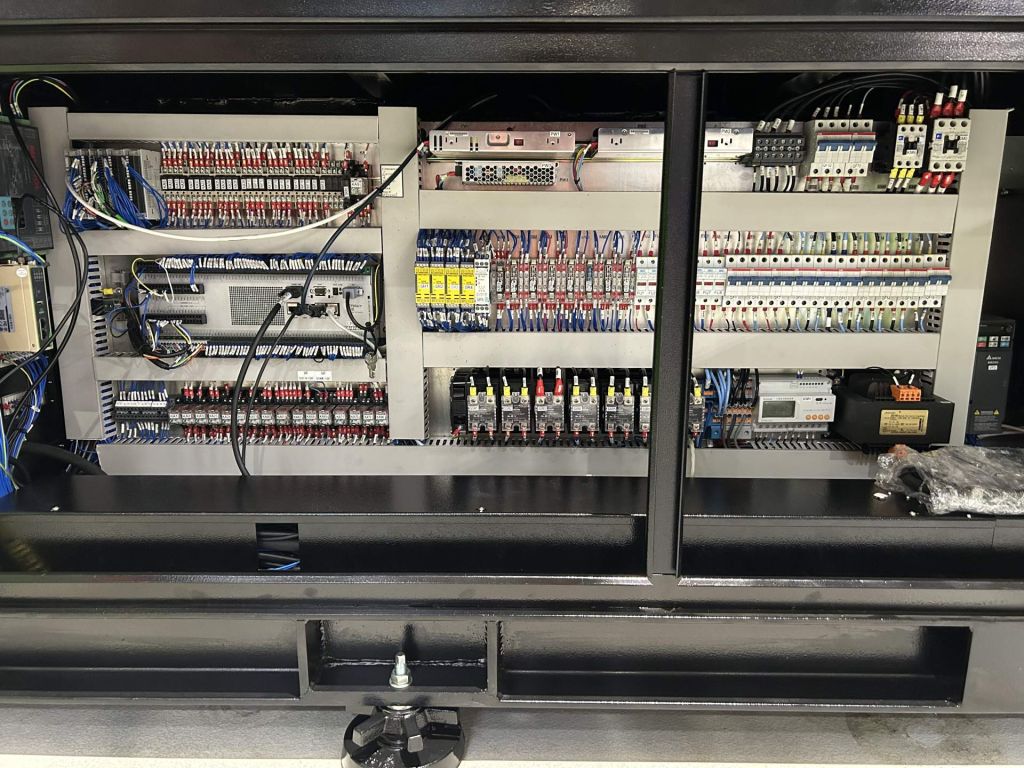

- Integrated servo-pump unit (standard), for control of auxiliary functions.

- Intuitive interface on 100% 21″ touch screen.

- SPC”, “QDP” functionality, graphics pages, energy-saving optimization page.

- Sequencer function for cycle management, free cores programming.

Options

- Various options can be added to the range such as: integrated mold heating zones, shutt off check valve control, hydraulic or pneumatic shutt off nozzle, retractable tie bars, magnetic platens, etc…

Do you need information?

Do not hesitate to contact us.