DIRECTPRO

The Long Fiber solution for producing large, high-strength parts.

AUTOMOTIVE: front module, trunk frame, door panel module, dashboard frame.

HOME APPLIANCES: washing machine drum, washing machine drum spider, air conditioning fans.

ELECTROMECHANICAL: deflector propeller blade, fan blade, water pump, vacuum pump.

FURNITURES: seats, formwork, etc.

LOGISTICS: freight boxes, pallets, transit boxes.

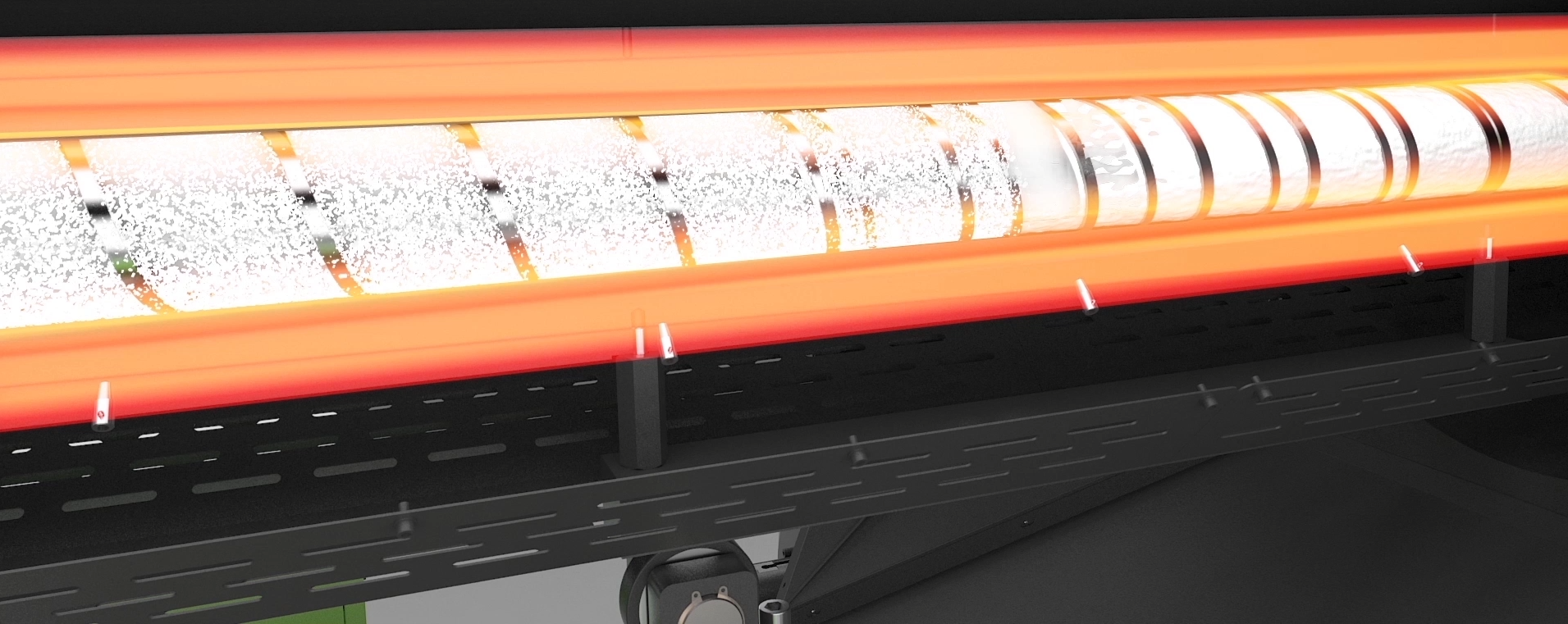

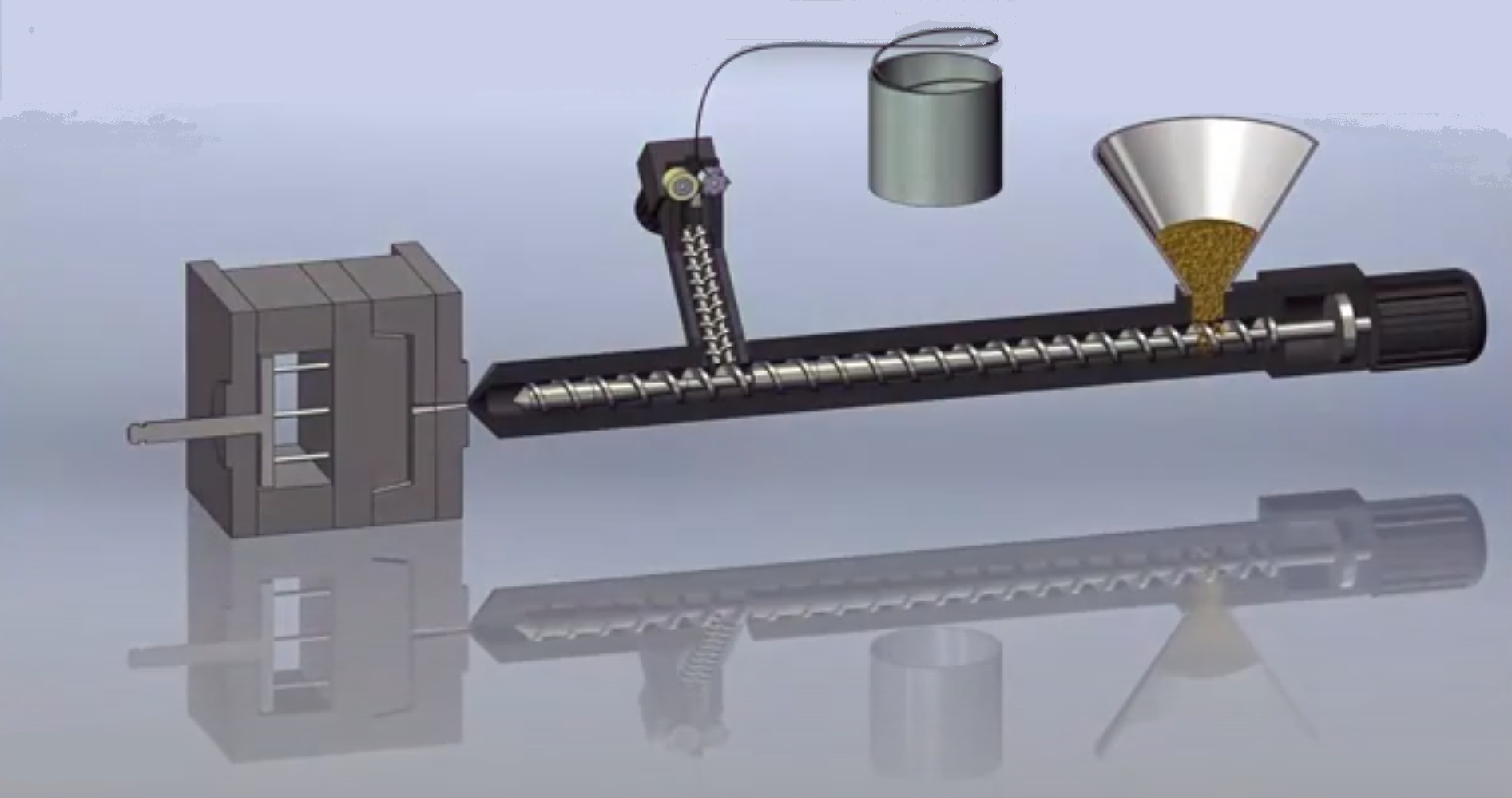

– The plastic pellets are transported after being melted in the first zone of the screw.

– The fibre bundles are measured and sheared to the required length before being fed into the barrel by a feeder.

– Once uniformly mixed with the melt in the second zone of the screw, the mixture is injected directly into the mould to produce the part.

1/ The long fibers are introduced into the molten plastic, the substrate at the front of the injection unit undergoing less mechanical stress in order to obtain fibers of optimal quality.

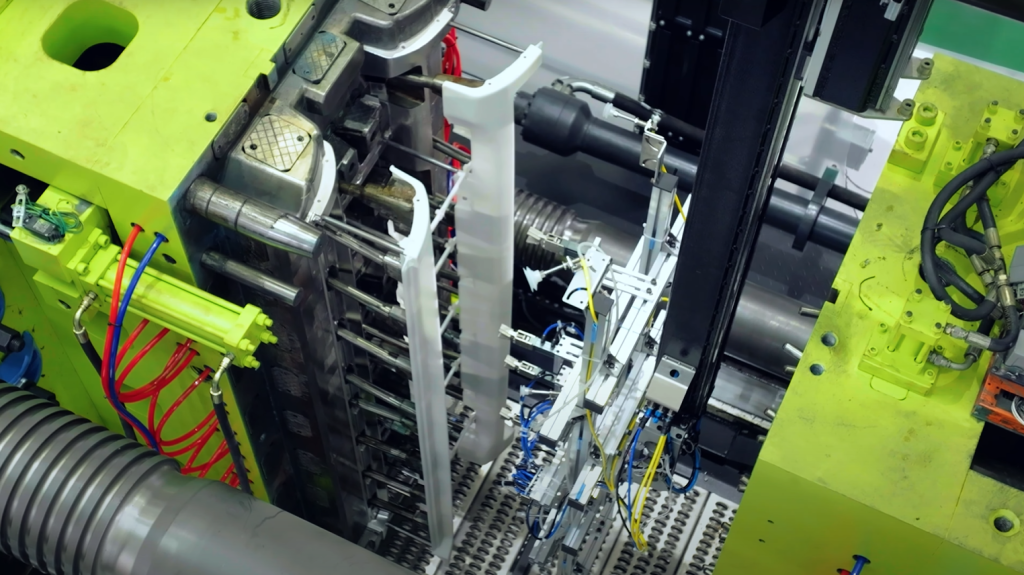

2/ Depending on the requirements of the parts to be produced, it is possible to independently adjust the fiber length (5-100mm) and rate (0-50%) without the need to change the raw material.

3/ The mechanical performance of the product is increased. DirectPro can be used as an alternative to engineering plastics with reduced production costs.

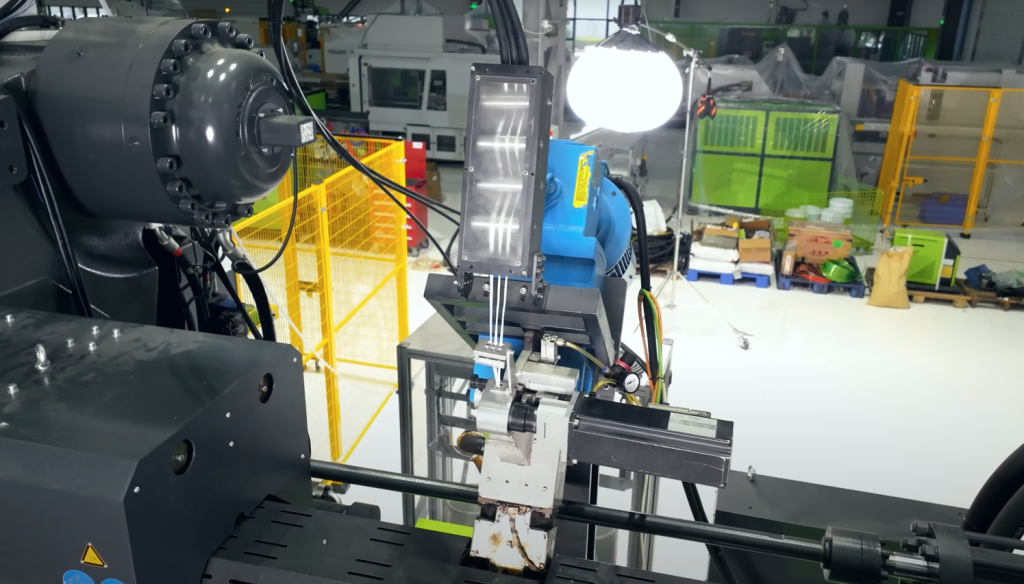

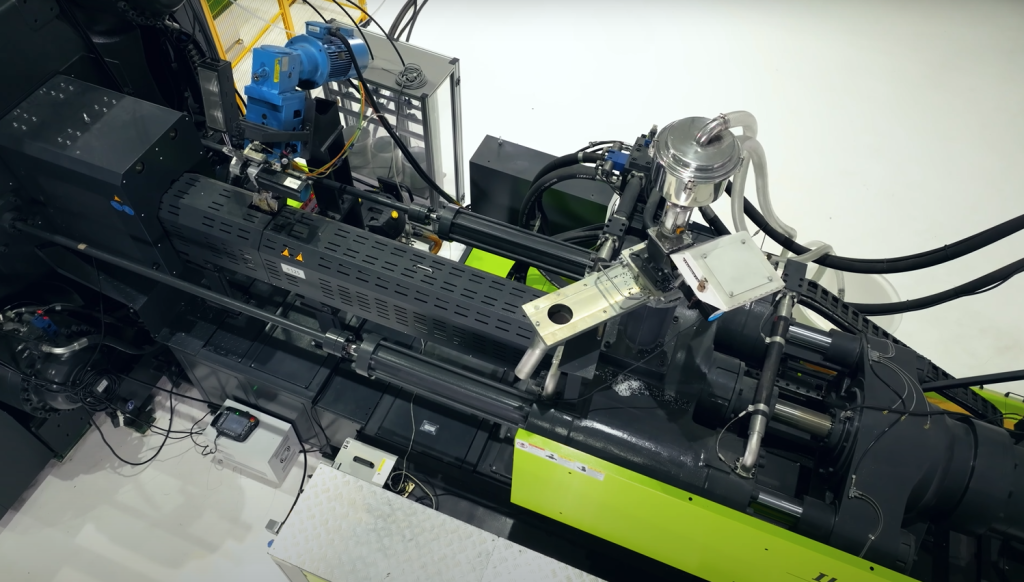

4/ Arrangement carried out on a standard machine, this still being possible in a conventional injection molding machine.

DirectPro

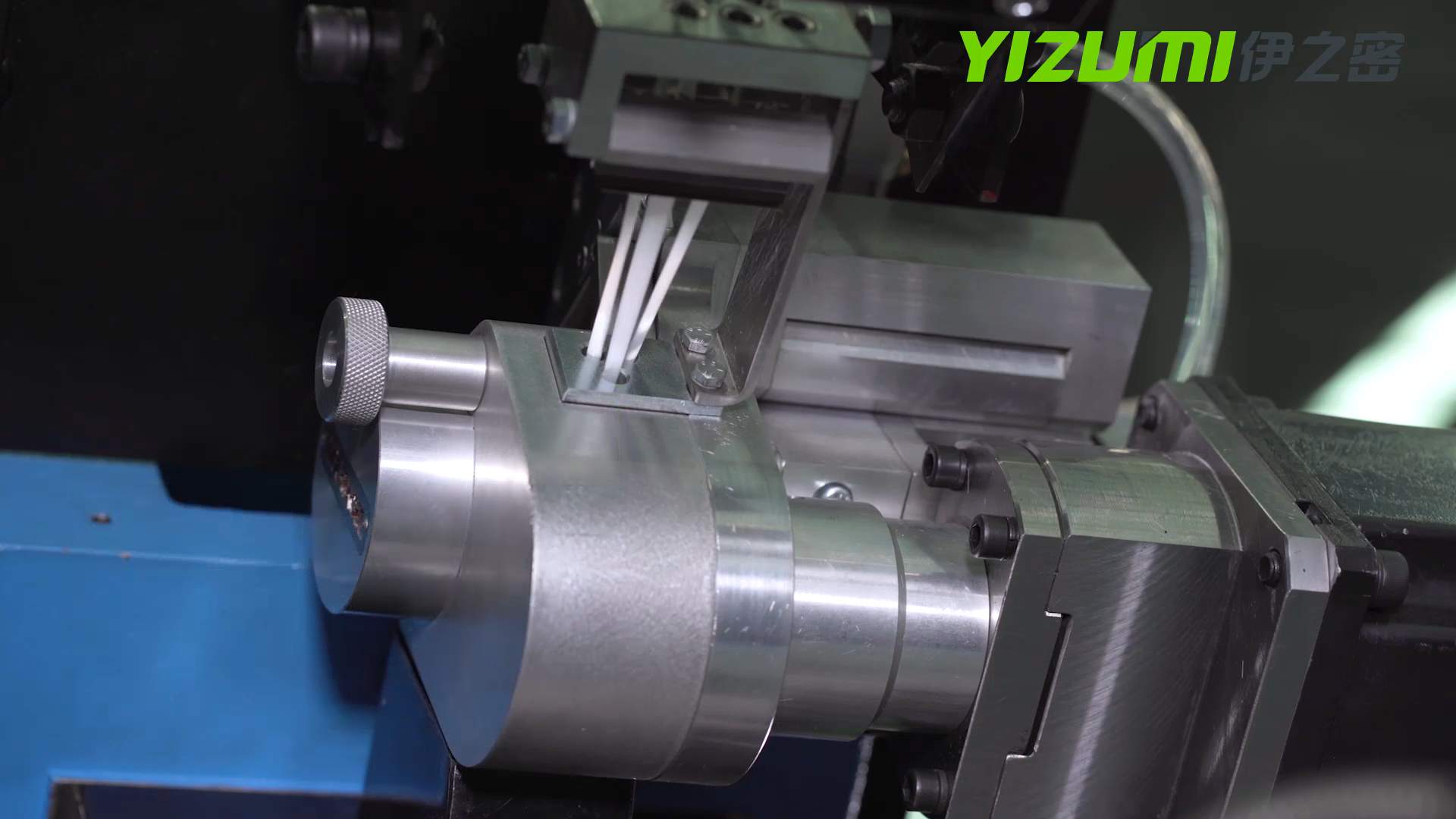

Application on YIZUMI 1850 D1: injection of long fibers automotive parts.

En images

Do you need information?

Do not hesitate to contact us.