DCIMPro Direct Compounding Injection Molding

Compounding of materials directly on the injection screw.

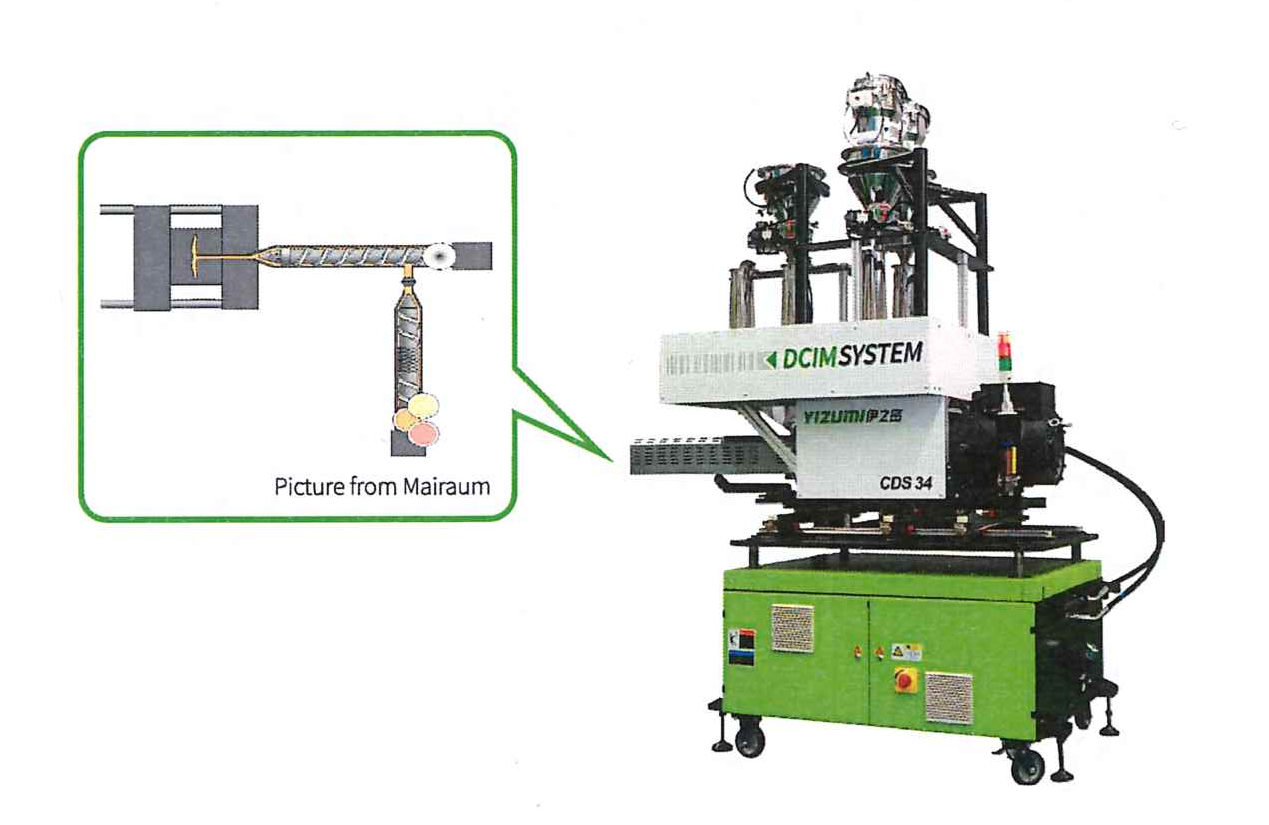

The CDS (Compound Delivery System)

– Combination of compounding and injection molding machine.

– CDS (Compound Delivery System) which can be combined with the 4 YIZUMI series or other brands.

– Reduction in production costs of up to 24% depending on the machine and the volume of the part.

– Gravimetric dosing and weighing system for products.

– 4 references of CDS 34/68/102/136 with increasing injectable volumes.

Advantages

For your production and parts

– No drying of materials required (energy savings and more stable production).

– Up to 30% improvement in plastification performance during operation of the machine combined with a CDS system.

– Processing of recycled materials without intermediate steps for the preparation of the material.

– Reduction of expensive additives.

– Production of plastic parts with optimized material combinations.

– Flexible production in combination with the CDS system or without.

DCIMPro

An industrial application: real-time compounding of a polymer based on PLA (polylactic acid) and additives in order to supply a 160t A5 press for biodegradable glass injector.

En images

Do you need information?

Do not hesitate to contact us.